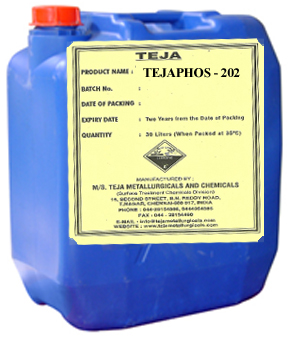

TEJA METALLURGICALS AND CHEMICALS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TEJA METALLURGICALS AND CHEMICALS

Forging Chemicals

Product description

Tejaphos - 202 is a heavy zinc phosphate compound, which produces excellent Zinc/Iron phosphate coating on Iron and steel supplementary finishes. This product needs accelerator addition in the bath periodically. The conversion coating produced with Tejaphos-202, when used in conjunction with suitable lubricant, reduce friction under low, medium and high forming on components when forged. Lubricants and drawing compounds become firmly anchored to the phosphate coating for improved forging.

Product Specifications

Colour

Light green liquid.

Chemical Composition

Blend of chemicals and additives.

Odour

Slightly Pungent

Foaming Tendency

Nil

Reliability

Good

Handling

Avoid skin contact

Solubility

Good

pH

Acidic Range

Toxicity

Acidic

Flash Point

Nil

Pollution Hazard

Treatable

Product Operating Data

Concentration

7.5% by v/v

Temperature

60-70°c

Time

10-15 min

Accelerator

2.0 – 3.5 ml

Product Operating Procedure

Pickling

Pickling should be carried out either in sulphuric or Hydrochloric Acid, in combination with suitable acid Inhibitors in sufficient strength to remove rust and scale present on the work.

Rinsing

The stage rinsing should be followed after the pickling process, first rinse with cold water and finally rinse with jet pressure. The rinsing tank should be cleaned regularly.

Phosphating

Fill the tank 2/3 with clean water and add recommended amounts of Tejaphos-202. Fill the tank to the operating level with water and mix thoroughly and for total acid and if necessary add enough Tejaphos-202 to bring total acid to operating level and mix thoroughly. Add 30-35 gm of Tejaactivator NP accelerator in the bath by dissolved in cold water. After phosphating with Tejaphos-202, the work should be rinsed with continuous flowing water and subsequently once again rinsed in hot neutralizing solution. The neutralizing solution is made up with 0.1 kg of soda ash per 100 litres of bath.

Operating Recommendation

Proper rinsing is very much essential after pickling in mineral acids, in order to remove the acid residues from the surface of the work. Any carry over of the acid to the phosphating tank will lead to excessive sludge formation leading to deterioration of phosphate coating and high chemical cost.

Proper control of temperature, pointage and time to minimise the chemical consumption.

Thin coating may result from a low bath temperature of insufficient treating time.

Product Application Equipment

Tejaphos-202 tank should be fabricated with 3 to 4 mm thick M.S. Plates with continuous convection current heating system.

Testing and Control Procedure

The Tejaphos-202 is controlled by simple titration for total acids. Ferrous Iron concentration of Tejaphos- (Accelerator) by titration method.

Total Acidity

Pipe out 10 ml. bath solution into a beaker. Add 5-10 drops of indicator Phenolphathalein. Fill the burette to the zero mark. And titrate with N/10 sodium Hydroxide solution. Stir the solution until pink colour appears. Note volume of N/10 Sodium Hydroxide solution used.

Free Acidity

Pipette out 10 ml. of bath solution into a beaker. Add 5-10 drops of Methyle Orange Indicator. Fill the burette to the zero mark and titrate with N/10 Sodium hydroxide Solution. Stir the solution until pink colour appears. Note volume of N/10 sodium Hydroxide solution used.

Accelerator Titration

Pipette out 10 ml. of bath solution into flask. Add 5 ml of concentration H2SO4 and mix, Titrate against N/10 Kmno4 solution a pink colour which will persist for few seconds. Note the number of ml of N/10 KmnO4 added in the solution. Normal limits of Tejaactivator (Accelerator) titration is 2-6 ml. Lower limit is preferable, Prior to titration. Starch lodide test should be positive. Approximately 30 ml of 25% Teja Activator (Accelerator) solution in water should be added to increase the Teja Activator (Accelerator) pointage by 1 ml.

Determination of Iron Contents

Pipette out 10 ml of bath solution in 150 ml. conical flask and titrate with N/10 KmnO4 (3.16gm/litrs) solution to a pink end point persisiting for 15 seconds. Multiply the titration reading with 0.56 to get percentage of ferrous Iron in the bath.

A fresh bath when aged with steel wool or steel scrap as described earlier should give ferrous Iron concentration of about ferrous 0.5% for a normal loading in the bath, the ferrous Iron concentration will stay with 0.05% o 4%.

Chemical Replenishment

Add 135 ml. Of Tejaphos-202 per 100 ltrs. Bath for each point lacking. The bath should be kept with in 1 ml of the specified titration values.

During the processing sludge is formed and the same is accumulated in the bottom of the tank. It should be removed at regular intervals. Sludge removal is carried out by decanting the clear solution is restored to its operating level by adding water and chemical in the recommended proportion as used in the original bath.

Safety Measures

Tejaphos-202 is an acidic liquid material, and while handling proper care should be taken. Protect eye, skin by means of goggles, aprons, gloves and face shield etc. If it comes in contact with skin and eyes wash thoroughly with a flush of water and get medical advice.

General Information

Corrosion Resistance: Excellent

Lubrication During Wire Drawing: Excellent.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.